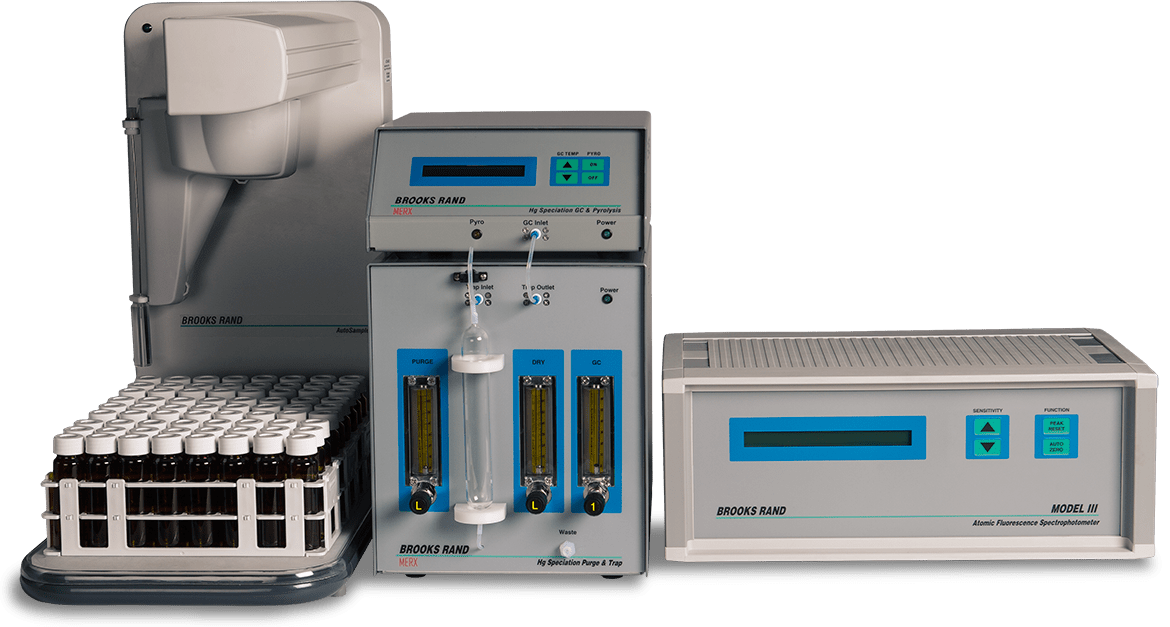

Automated Mercury System

MERX-M

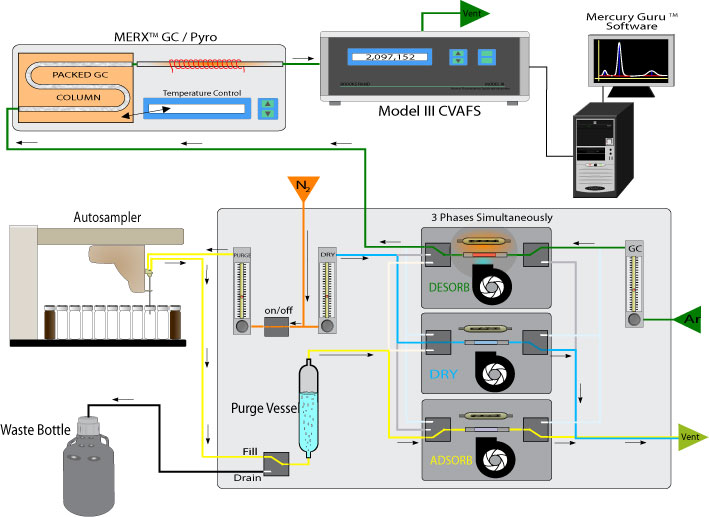

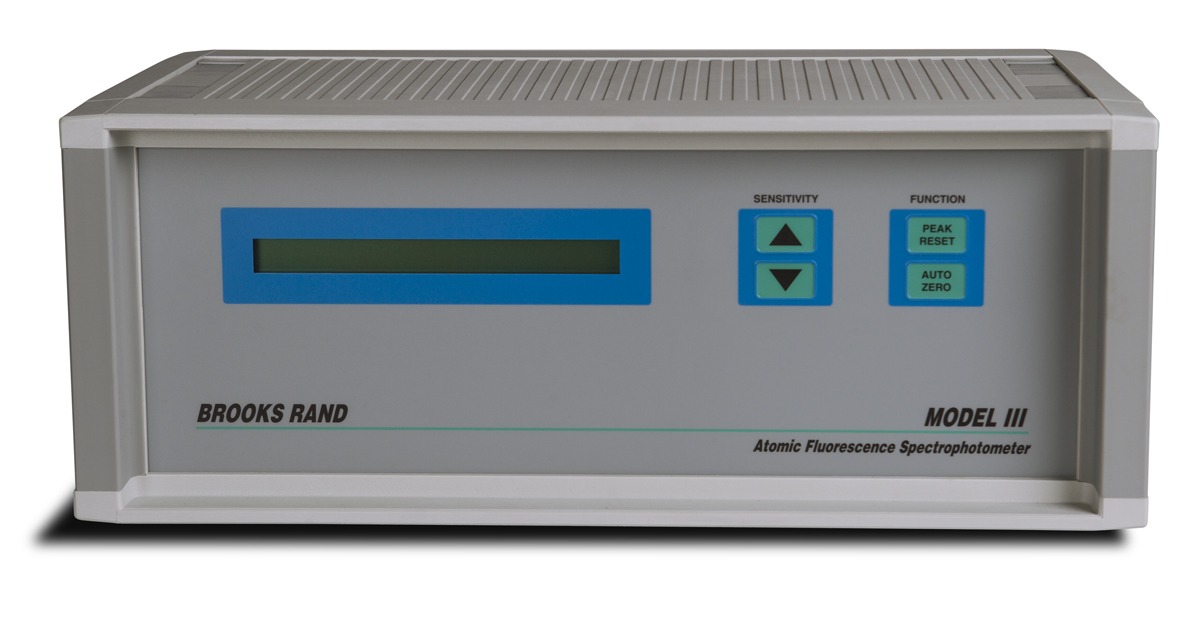

In use at Brooks Rand Labs since 2006 and introduced commercially in 2007, MERX is the world’s first commercial automated analytical system based on US EPA Method 1630 for methylmercury analysis. Around the world, numerous national environmental agencies and leading universities have quickly embraced MERX as an easy-to-use, robust, and reliable system that delivers high quality data.