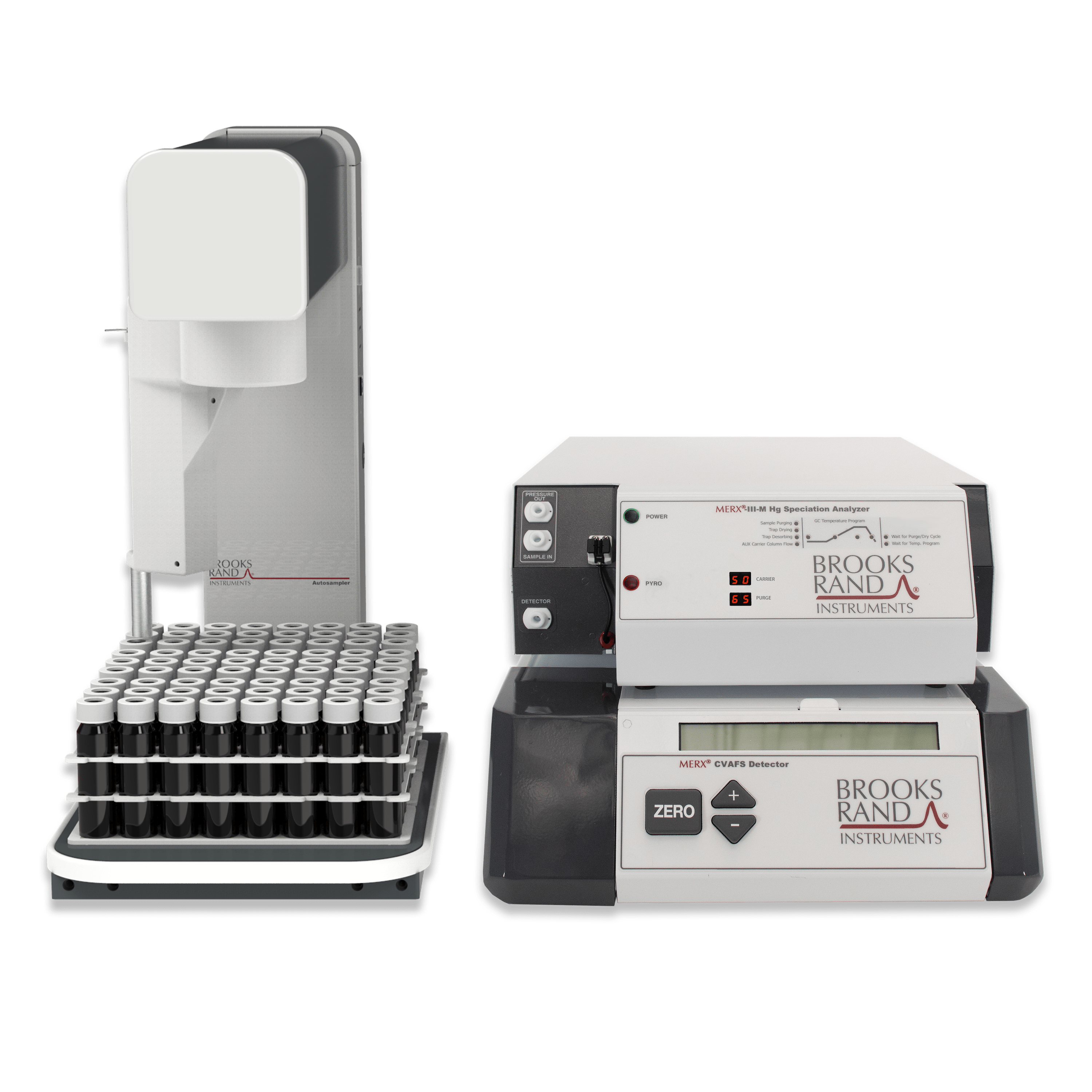

Automated MethylMercury System

MERX-III-M

New from Brooks Rand! Inspired by years of experience and feedback, Brooks Rand is pleased to introduce a “simpler” model of automated system, but with advanced features to speed sample throughput!

New from Brooks Rand! Inspired by years of experience and feedback, Brooks Rand is pleased to introduce a “simpler” model of automated system, but with advanced features to speed sample throughput!

Sample Preparation

Prior to analysis, samples are prepared as per normal methylmercury methodology, typically distillation for water (US EPA 1630), extraction for sediment or digestion for tissue.

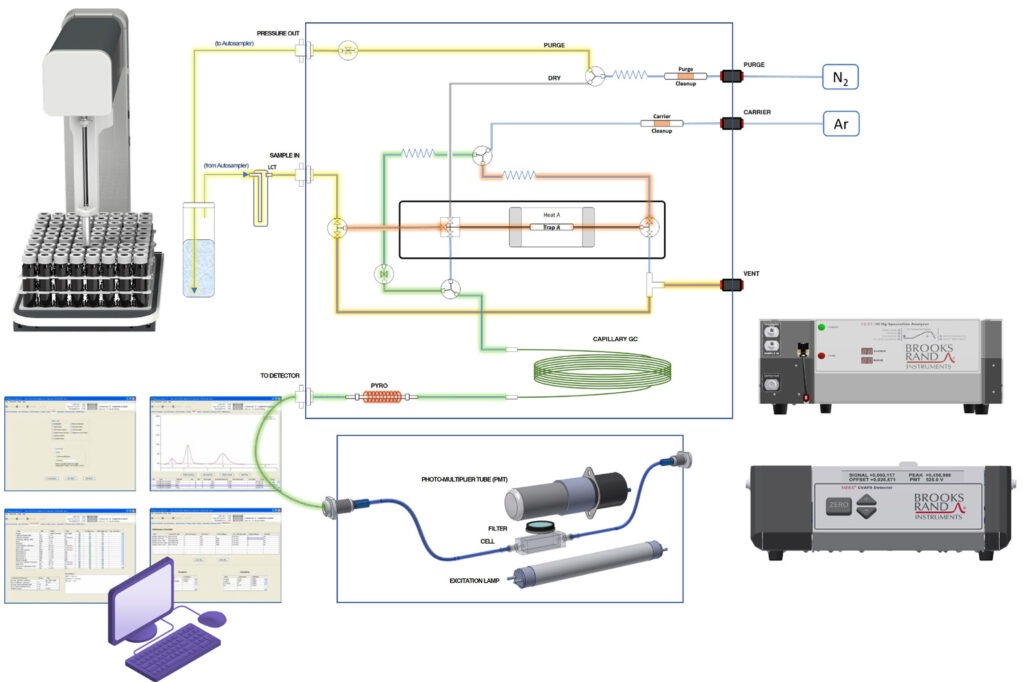

Vial Loading

Prepared samples are added to 40 mL vials with Teflon® lined septa caps. Samples are buffered and ethylated with the addition of NaBEt4. The vials are then capped, shaken and placed in the autosampler.

Software Setup

Sample information is entered into Mercury Guru™ software, settings are selected and then sample analysis begins. MERX does the rest!

Liquid Handling

As each vial is pierced, the purge gas transfers volatile ethylated Hg species onto a Tenax® trap.

Sample Processing

The trap collects ethylated Hg species from the vial. During drying of the sample on the trap, purge gas continues to flow through the sample vial and transfer line to remove any residual volatile mercury compounds. After drying, the trap is rapidly heated and cooled to release the sample into the column. Once the sample is on the column, an auxiliary carrier gas valve allows the trap to be loaded with the next sample.

GC Separation

The released Hg species are separated on a GC column and then thermally reduced to elemental mercury.

CVAFS Detection

Mercury is detected using the Brooks Rand Model IV cold vapor atomic fluorescence spectrophotometer (CVAFS) with patented optics for enhanced sensitivity.

Data Processing

Mercury Guru™ software integrates the detector signal and calculates results based on calibration and sample volume information. QC results are automatically flagged based on user defined criteria.

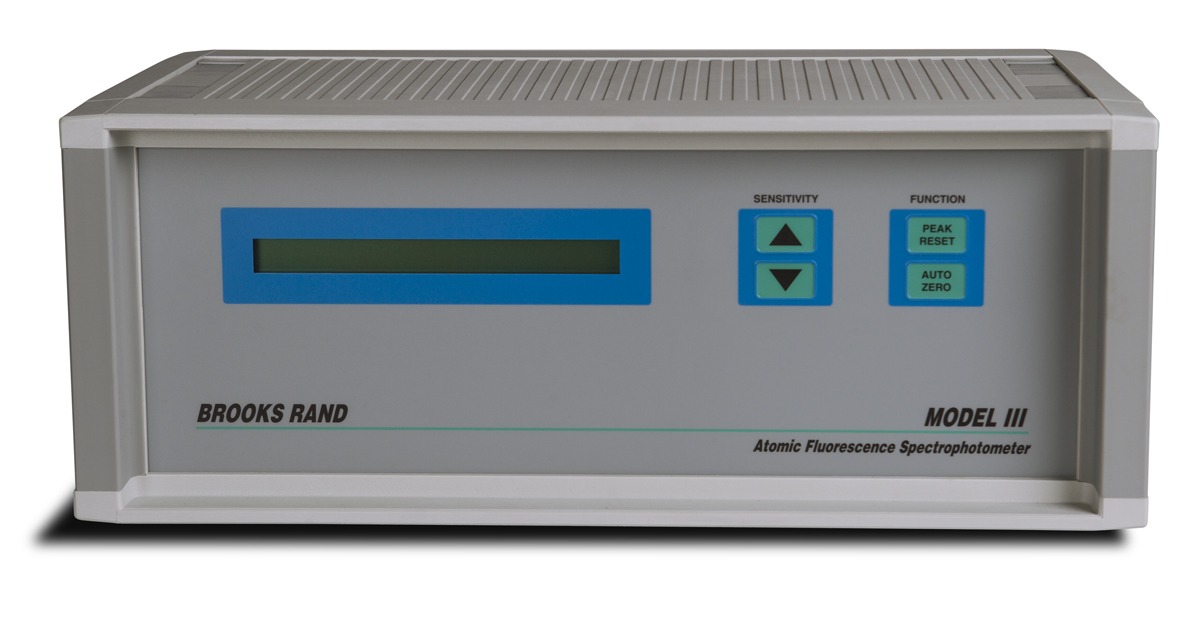

The Brooks Rand Model III was designed with input from leading mercury researchers from around the world to meet the most demanding analytical requirements and is cited in US EPA Methods 1631, 245.7, and 1630. With the ability to adjust the sensitivity across a broad dynamic range and with one-button auto baseline zeroing, the Model III is an incredibly stable detector that can run continuously all day without recalibration and is one of the most reliable mercury detectors in use today.

Requires PC with at least one RS-232 serial port and one USB port (can be supplied by Brooks Rand Instruments or customer-supplied)

TBA

A 72-position autosampler provides fast and easy analysis of all calibration, quality control, and normal samples through one robust system and with minimal supervision. The MERX® Autosampler design results in a system that generates considerably less waste and requires less maintenance than a flow-through system with a gas-liquid separator.

The purge and trap module controls all of the gas flows throughout the system. It contains Tenax traps, which capture mercury species, and controls their heating and cooling. It contains the purge vessel, where samples are transferred to be purged onto the Tenax traps.

The GC and pyrolysis module contains a packed chromatographic column that separates out he mercury species from each sample, once they are released from the Tenax traps. The species emerge as separate peaks that can be individually quantified by the detector. The pyrolysis column, downstream of the chromatographic column, thermally decomposes each mercury species to elemental mercury vapor, the only form of mercury to which the detector is sensitive. This module is included in the following systems: MERX-M, Methylmercury Manual System.